Add to Cart

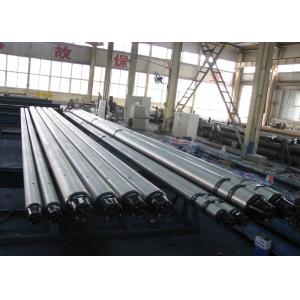

Directional Downhole Drilling Tools, Non-Magnetic Drill Collar, P530, P110

Tiptop provides excellent Non-Magnetic Drill Collar for Directional Drilling. Non magnetic material is high purity austenitic stainless steel. Strict control of chemical composition and special forging process guarantee the excellent mechanical properties of our non magnetic drill collar.

Non Magnetic Properties:

Relative Permeability: Max. 1.005

Hot Spot/Field Gradient: Max ±0.05μT

Special Treatment on ID: Roller Burnishing. (after roller burnishing, a comprehensive layer come into being)

Advantages:

Increase the corrosion resistance properties;

Increase the surface hardness of bore up to HB400;

Increase surface finish of bore to Ra≤3.2μm

Test and inspection carried out on each bar during production :

Chemical Composition;

Tensile Test;

Impact Test;

Hardness Test;

Metallographic Test (Grain Size);

Corrosion Test (According to ASTM A262 Practice E);

Ultrasonic Test over the whole length of the bar (according to ASTM A388);

Relative magnetic permeability test;

Hot Spot Test;

Dimension Inspection, etc.

Please contact us for your non-magnetic drill collar inquiries.

Specification of non magnetic drill collars:

| Tool Joint | OD in | Bore d in + 1/16 -0 | Length ft +6 -0 | Bevel Diameter in ±1/64 in | BSR |

| NC23-31 | 3 1/8 | 1 1/4 | 30 | 3 | 2.57:1 |

| NC26-35 | 3 1/2 | 1 1/2 | 30 | 3 17/64 | 2.42:1 |

| NC35-41 | 4 1/8 | 2 | 30 or 31 | 3 61/64 | 2.43:1 |

| NC35-47 | 4 3/4 | 2 | 30 or 31 | 4 33/64 | 2.58:1 |

| NC38-50 | 5 | 2 1/4 | 30 or 31 | 4 49/64 | 2.38:1 |

| NC44-60 | 6 | 2 1/4 | 30 or 31 | 5 11/16 | 2.49:1 |

| NC44-60 | 6 | 2 13/16 | 30 or 31 | 5 11/16 | 2.84:1 |

| NC44-62 | 6 1/4 | 2 1/4 | 30 or 31 | 5 7/8 | 2.91:1 |

| NC46-62 | 6 1/4 | 2 13/16 | 30 or 31 | 5 29/32 | 2.63:1 |

| NC46-65 | 6 1/2 | 2 1/4 | 30 or 31 | 6 3/32 | 2.76:1 |

| NC46-65 | 6 1/2 | 2 13/16 | 30 or 31 | 6 3/32 | 3.05:1 |

| NC46-67 | 6 3/4 | 2 1/4 | 30 or 31 | 6 9/32 | 3.18:1 |

| NC50-70 | 7 | 2 1/4 | 30 or 31 | 6 31/64 | 2.54:1 |

| NC50-70 | 7 | 2 13/16 | 30 or 31 | 6 31/64 | 2.27:1 |

| NC50-72 | 7 1/4 | 2 13/16 | 30 or 31 | 6 43/64 | 3.12:1 |

| NC56-77 | 7 3/4 | 2 13/16 | 30 or 31 | 7 19/64 | 2.70:1 |

| NC56-80 | 8 | 2 13/16 | 30 or 31 | 7 31/64 | 3.02:1 |

| 6 5/8 REG | 8 1/4 | 2 13/16 | 30 or 31 | 7 45/64 | 2.93:1 |

| NC61-90 | 9 | 2 13/16 | 30 or 31 | 8 3/8 | 3.17:1 |

| 7 5/8 REG | 9 1/2 | 3 | 30 or 31 | 8 13/16 | 2.81:1 |

| NC70-97 | 9 3/4 | 3 | 30 or 31 | 9 5/32 | 2.57:1 |

| NC70-100 | 10 | 3 | 30 or 31 | 9 11/32 | 2.81:1 |

| 8 5/8 REG | 11 | 3 | 30 or 31 | 10 1/2 | 2.84:1 |

Mechanical Properties:

| Steel Grade | OD Range in | Yield Strength Rt | Tensile Strength Rm | Elongation A (%) | Impact Value Akv | Hardness Brinell (HB) | ||

| Mpa | ksi | Mpa | ksi | |||||

| SLW-1 | 3 1/8 through 6 7/8 | ≥758 | ≥110 | ≥827 | ≥120 | ≥25 | ≥150 longitudinal | 285-360 |

| 7 through 11 | ≥689 | ≥100 | ||||||

| SLW-2 | 3 1/8 through 6 7/8 | ≥827 | ≥120 | ≥896 | ≥130 | ≥25 | ≥150 longitudinal | 285-360 |

| 7 through 11 | ≥758 | ≥110 | ||||||

| SLW-3 | 3 1/8 through 6 7/8 | ≥765 | ≥140 | ≥1034 | ≥150 | ≥20 | ≥90 longitudinal | 330-400 |

| 7 through 11 | ≥896 | ≥130 | ||||||

| SLW-4 | 3 1/8 through 6 7/8 | ≥827 | ≥120 | ≥896 | ≥130 | ≥20 | ≥75 longitudinal | 285-360 |

| 7 through 11 | ≥758 | ≥110 | ||||||